Space utilization and operational efficiency are paramount in cold storage warehouses. With their restricted cubic volume and costly energy, companies need racking systems that maximize density without hindering convenient forklift access. ...

Space utilization and operational efficiency are paramount in cold storage warehouses. With their restricted cubic volume and costly energy, companies need racking systems that maximize density without hindering convenient forklift access.

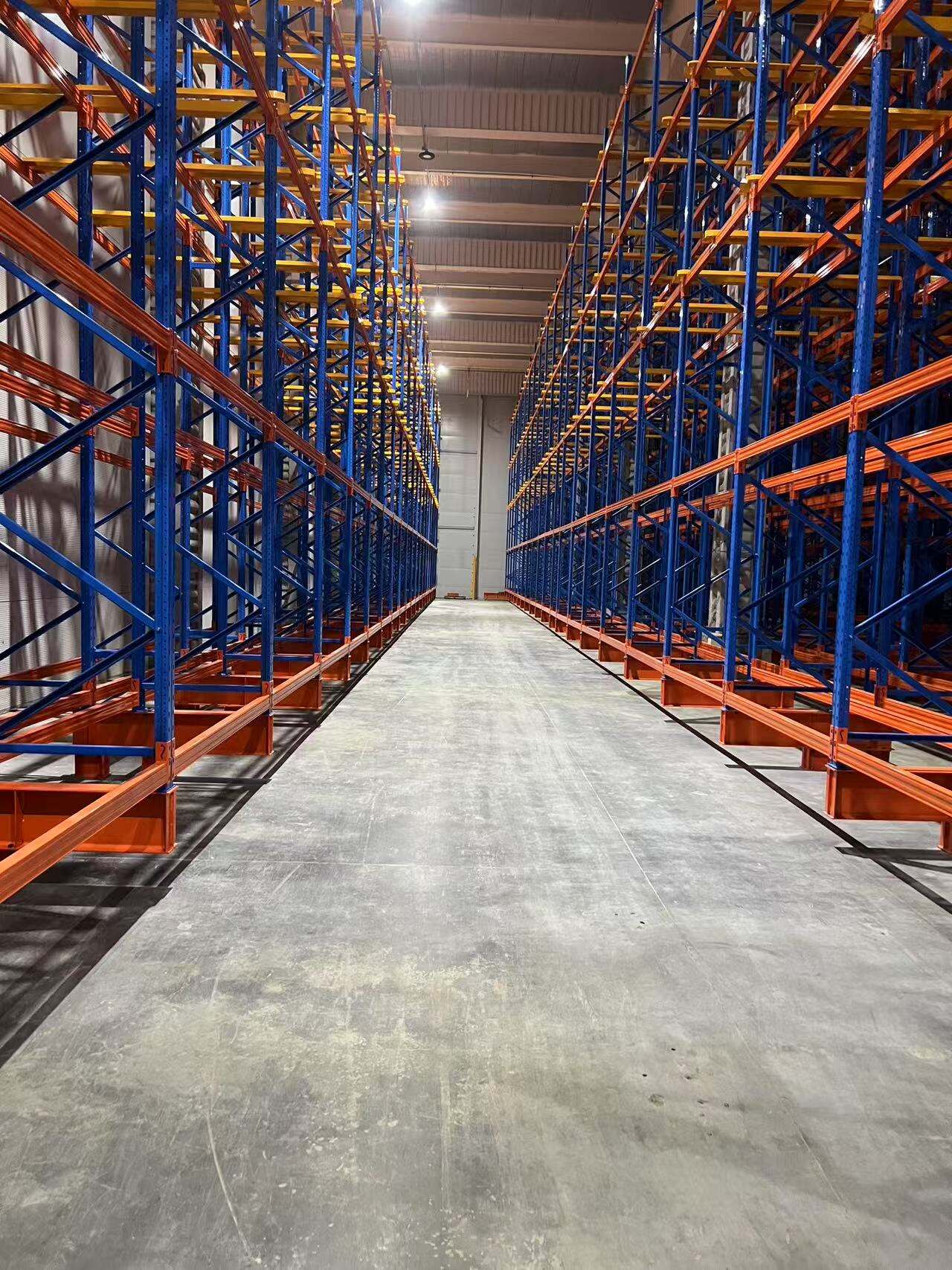

For this project, Everunion specially designed and supplied a Double Deep Pallet Racking system that is specifically adaptable to cold room application. A special feature for this design is the cantilevered base which allows compatibility with a specialized forklift. This enables convenient handling of pallets and optimizes the utilization of floor space.

Why Double Deep in Cold Rooms?

•High Density Storage: Stores two pallets deep, doubling capacity compared to selective racking

• Energy Efficiency: Reduces cooling costs by maximizing cubic space

• Custom Adaptation: Utilizes cantilevered base design to integrate seamlessly with custom forklifts for efficient and safe operation in the confined cold room area

The client was able to increase storage density without expanding the facility, reduce energy costs by more efficient use of space, and streamline cold chain operations with customized racking and forklift compatibility