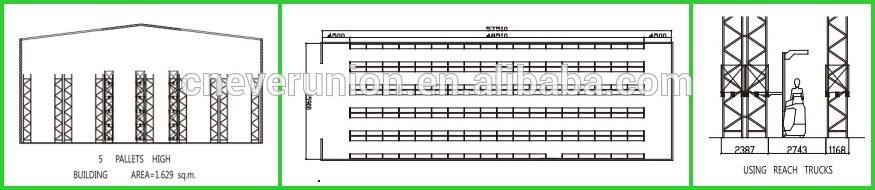

Standard Pallet Rack is the most common form of storage rack. Pallets of materials are placed directly on the rack system by a forklift. Each load in pallet racks is readily accessible, making the 100% selective storage rack systems are both economical and efficient. Pallet rack designs come in numerous configurations to handle any storage need and can be easily expanded as your company grows. They are well built and extremely durable.

Warehouse picking equipment

Features of pallet racking system:

1. Pallets can be located, accessed and moved individually.

2. Rapid handling of almost all types of palletized goods.

3. Different sizes, various specifications and colors are available according to different needs.

4. Easy access to installment and simple to adjust by the pitch of 75mm or 76mm.

5. Strength and rigidity prevents compression damage to goods.

6. Bottom level of pallets can be stored on the floor, lowering structure costs.

Three upright rack is also acceptable, then the depth can be max 2400mm.

|

Load Capacity & Dimension: |

|

| Surface treatment |

|

Material: |

High-quality Q235B steel plate purchased from the big steel Group in China. |

Others: |

|

Please inform us the listed information for a quick quotation of pallet rack:

1) drawings of your warehouse or rack system if possible

2) Your pallet size: Height (with goods)*Depth*Length? Which side is for forklift entry?

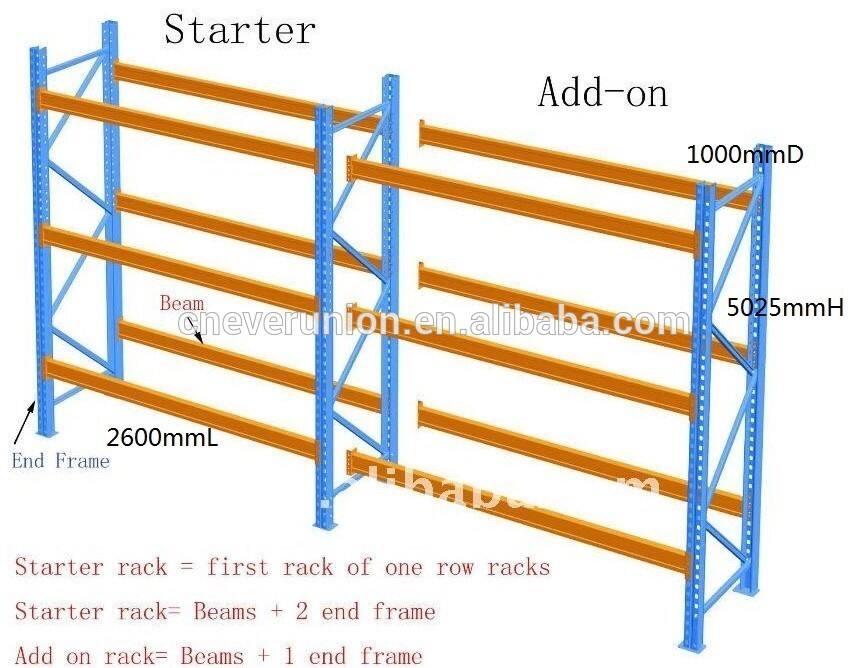

3) How many start bays and add on bays you want.

4) Clear warehouse height or Max forklift lifting height

5) Loading capacity of each level

6) Aisle width needed for forklift operation, as common 3000mm

We can provide free and professional warehouse rack Auto CAD drawing design based on your these above info, to solve your warehouse storage solutions.

Or pls let us know your rack size(H*D*W), nons of level, loading each level, qty of starter rack + Add-on rack.

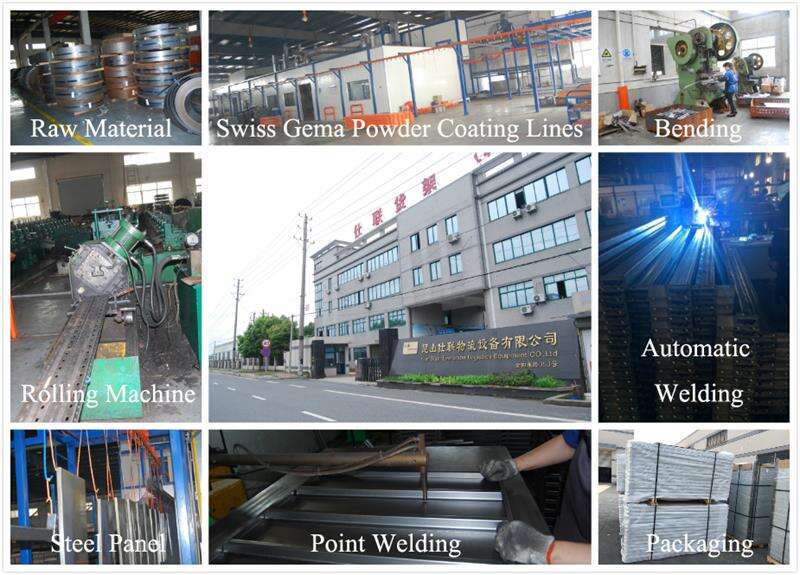

KUNSHAN FACTORY PHOTO

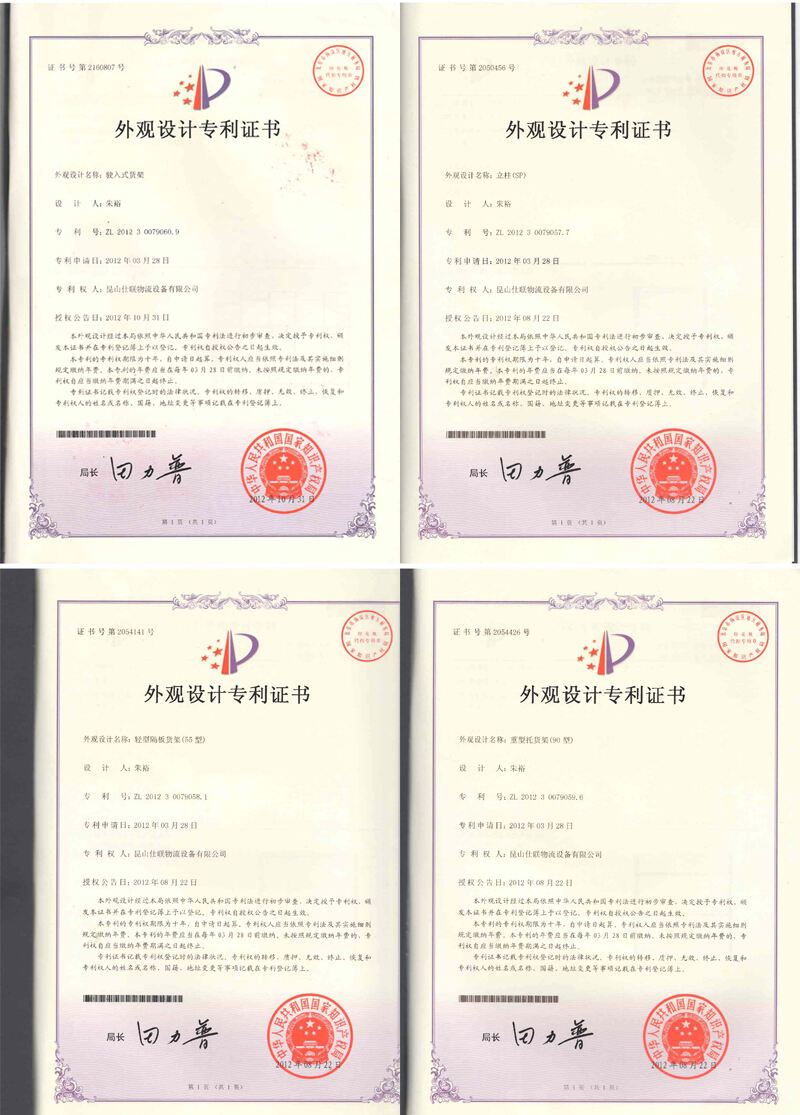

PATENT for RACK DESIGN

CE and ISO CERTIFICATE

TEST REPORT

Q1: Are you a manufacturer or trading company?

A: We are a professional racking manufacturer in Kunshan, Jiangsu, we have sales office in shanghai. From shanghai to our factory, it will take about 1 hours by car.

Q2: what is your warranty time?

A: The high standards in the design and manufacturing ensure us to support the products with a 10 years warranty time for your normal use, it is the longest manufacturer's warranty!

Q3: What is delivery times?

A: We have 2 GEMA powder coating lines and 4 automatic welding machines, which can ensure us very short delivery time—less than 18 days.

Q4: What is your payment term?

A: 1) As general, 30% T/T down payment and 70% against BL copy.

2) 100% LC at sight

Q5: Are samples available?

A: Yes, we can send some sections of samples for your reference by express.

Q6: what’s the loading port?

A: Shanghai port is the closest port to us.

Q7: what’s the material and finishing of your racks?

A: As general, our material is Steel Q 235, Finishing: Powder coating.

Q8: How can I get your quick quotation on my pallet racking project?

A: As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotation, we need to know the following information

1) Required Pallet Racking Dimension: Height*Depth*Length?

2) Number of Levels?

3) Loading Capacity of each level?

4) Racking Quantity?

Q9: How many racks could be fit into a 20' container or a 40' container

A: We coud tell you if you provide us below information:

1) rack dimension

2) rack quantities

3) rack loading weight

Our Advantage

1) Our quick reply

For a quick quotation, just send email to us. We promise to reply with a price within 12 hours

2) Our short delivery time

For selective pallet racking orders, we will promise to produce within 15 days. As a manufactory we can essure the delivery time according to the formal contract.

3) Our special exporting packages.

We have plastic clips on the beams to protect the beams from surface damage in the transportation, We have got the whole uprights wrapped with transparent plastic film.

4) More than 14 years experience on rack manufacturing and export

EVERUNION

The Sale hot Gravity Roller Racking techniques Customized Heavy-Duty Carton Flow Racks is the solution ideal any warehouse or storage area center wanting to optimize their storage space while increasing effectiveness. These racking systems are available with durability and quality at heart within the brand.

These racking systems are created gravity using and roller technology, which means that services and products can easily slip straight down and move ahead on their own, decreasing the necessity for handbook work. The EVERUNION movement normally managed, generally there is not any threat of products and services crashing into one another or harm causing. This design revolutionary that items are saved properly and effortlessly, while additionally enabling quick access and retrieval.

The High-Quality Carton Flow Racks are customizable, supplying the freedom to comply with any storage area requirement. Which means that clients could cause a racking personalized that works perfect for their requirements. You will need whether you will need a system to help keep hefty and things cumbersome or tiny items that need exact company, these racks could be tailored to match what.

In addition, EVERUNION Hot Sale Gravity Flow Roller Racking techniques are made to withstand usage hefty. Their construction guarantees high-quality component is durable and could be relied on. What this means is less upkeep and a lifespan extended of racking systems., the modification choices permit effortless changes as required, helping reduce upkeep ongoing.

The acquisition Gravity hot Roller techniques are created to be an easy task to install. The racking systems are pre-assembled, so installation is finished quickly and effortlessly. The technique whole hassle-free, allowing you to begin using your brand-new racking systems as quickly as possible.

The Sale hot Gravity Roller Racking techniques Customized Heavy-Duty Carton Flow Racks are an investment very good any storage space center. Utilizing their customizable choices, durable construction, and easy installation, they provide an economical solution in making the essential of space for storage and effectiveness increasing. Being an EVERUNION item, you may like to trust they are developed to last and perform to the greatest criteria

CE certificated heavy duty warehouse picking equipment storage rack

Standard Pallet Rack is the most common form of storage rack. Pallets of materials are placed directly on the rack system by a forklift. Each load in pallet racks is readily accessible, making the 100% selective storage rack systems are both economical and efficient. Pallet rack designs come in numerous configurations to handle any storage need and can be easily expanded as your company grows. They are well built and extremely durable.

Warehouse picking equipment

Features of pallet racking system:

1. Pallets can be located, accessed and moved individually.

2. Rapid handling of almost all types of palletized goods.

3. Different sizes, various specifications and colors are available according to different needs.

4. Easy access to installment and simple to adjust by the pitch of 75mm or 76mm.

5. Strength and rigidity prevents compression damage to goods.

6. Bottom level of pallets can be stored on the floor, lowering structure costs.

Three upright rack is also acceptable, then the depth can be max 2400mm.

|

Load Capacity & Dimension: |

|

| Surface treatment |

|

Material: |

High-quality Q235B steel plate purchased from the big steel Group in China. |

Others: |

|

Please inform us the listed information for a quick quotation of pallet rack:

1) drawings of your warehouse or rack system if possible

2) Your pallet size: Height (with goods)*Depth*Length? Which side is for forklift entry?

3) How many start bays and add on bays you want.

4) Clear warehouse height or Max forklift lifting height

5) Loading capacity of each level

6) Aisle width needed for forklift operation, as common 3000mm

We can provide free and professional warehouse rack Auto CAD drawing design based on your these above info, to solve your warehouse storage solutions.

Or pls let us know your rack size(H*D*W), nons of level, loading each level, qty of starter rack + Add-on rack.

KUNSHAN FACTORY PHOTO

PATENT for RACK DESIGN

CE and ISO CERTIFICATE

TEST REPORT

Q1: Are you a manufacturer or trading company?

A: We are a professional racking manufacturer in Kunshan, Jiangsu, we have sales office in shanghai. From shanghai to our factory, it will take about 1 hours by car.

Q2: what is your warranty time?

A: The high standards in the design and manufacturing ensure us to support the products with a 10 years warranty time for your normal use, it is the longest manufacturer's warranty!

Q3: What is delivery times?

A: We have 2 GEMA powder coating lines and 4 automatic welding machines, which can ensure us very short delivery time—less than 18 days.

Q4: What is your payment term?

A: 1) As general, 30% T/T down payment and 70% against BL copy.

2) 100% LC at sight

Q5: Are samples available?

A: Yes, we can send some sections of samples for your reference by express.

Q6: what’s the loading port?

A: Shanghai port is the closest port to us.

Q7: what’s the material and finishing of your racks?

A: As general, our material is Steel Q 235, Finishing: Powder coating.

Q8: How can I get your quick quotation on my pallet racking project?

A: As different clients and projects have different needs of racking dimensions and specification, as general, for quick quotation, we need to know the following information

1) Required Pallet Racking Dimension: Height*Depth*Length?

2) Number of Levels?

3) Loading Capacity of each level?

4) Racking Quantity?

Q9: How many racks could be fit into a 20' container or a 40' container

A: We coud tell you if you provide us below information:

1) rack dimension

2) rack quantities

3) rack loading weight

Our Advantage

1) Our quick reply

For a quick quotation, just send email to us. We promise to reply with a price within 12 hours

2) Our short delivery time

For selective pallet racking orders, we will promise to produce within 15 days. As a manufactory we can essure the delivery time according to the formal contract.

3) Our special exporting packages.

We have plastic clips on the beams to protect the beams from surface damage in the transportation, We have got the whole uprights wrapped with transparent plastic film.

4) More than 14 years experience on rack manufacturing and export