EVERUNION knows that technology really has the power to simply make people's work life easier and better. One great example of this tech is something called automated storage, or AS/RS for short. This unique system is developed for enhancing the functioning and management of warehouses and their products.

An AS/RS, or automated storage and retrieval system, is a series of computer-controlled machines that automatically place and retrieve loads from designated storage locations. That means warehouses aren’t dependent on humans to perform all the heavy lifting by hand. Instead they can let machines do much of the work, resulting in speedier work and fewer errors. This is significant as it enables everything else to run smoothly and efficiently.

A significant advantage of an AS/RS in a warehouse is that it greatly simplifies inventory management and control. The system monitors the number of items in stock using machines that automatically store and retrieve items. This helps ensure that everything is always in the proper locations, and nothing is lost.

And this is beneficial for the companies dealing with specifically a high amount of inventory. That can be a very challenging and tiring task to keep a count of many items manually. But with a AS/RS this process is easier and far more accurate. This also means less waste and better results on all fronts, a real win-win for the company.

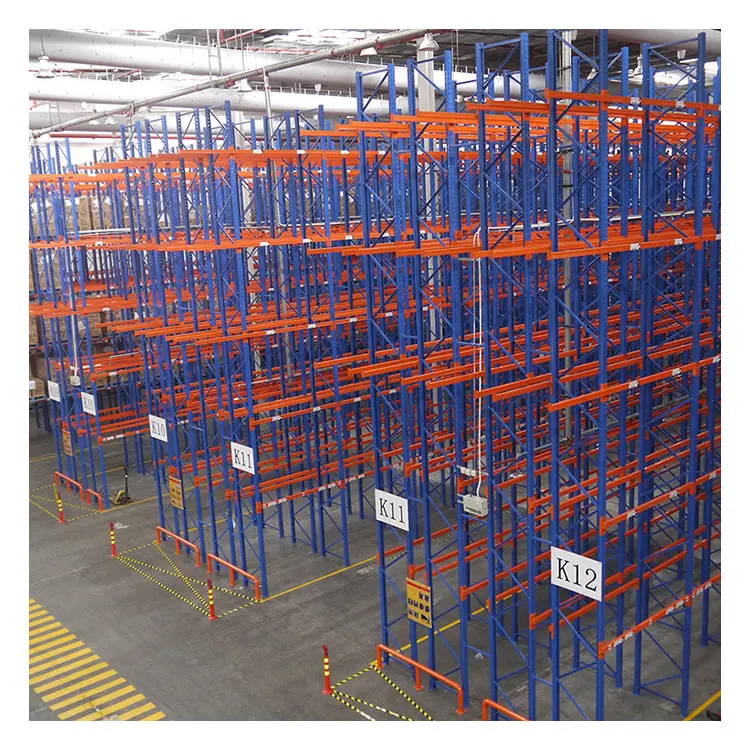

As another benefit, an AS/RS can also help utilize space in the warehouse better and make the overall process run more efficiently. Since the system is operated by a computer, it can organize items in a far more organized manner than human employees. This organization is fundamental for utilizing spaces to their maximum.

The warehouse can store more items in the same amount of land when it uses AS/RS. This is extremely important because the more products that companies can hold without having to expand their warehouses, the more sales opportunities there are. And it’s less time and effort to recover items when necessary. It makes for a more effective and profitable business, which is good for the company and its customers.

Warehouse staff can track orders and package them ready for shipping using scanners or automated retrievalsystems. Since these systems are so good at the heavy lifting, it can lead to workers seizing and packing orders much faster than if everything was done manually. Not only does this save time and effort, but it also increases the probability of no errors in the orders being delivered, which in turn ensures more satisfied customers receiving their orders correctly and on time.

Everunion offers a broad range of storage options to meet the various requirements of customers, from customized designs to a variety of racks. Our ability to provide customized solutions will ensure that each customer's unique requirements are fulfilled with accuracy.

We keep a close eye on costs by sourcing our raw materials directly. This allows us to provide competitive prices without compromising quality. Our comprehensive after-sales and pre-sales services, in conjunction with extended warranties provide our customers with peace of mind and added value.

Everunion has more than 20 years of experience and ensures that products are of high quality, precision, and meet the demanding standards of customers from all over the world. We have the ability to cut down lead times through an efficient approach and streamlining production processes.

Everunion operates on a huge campus, with state-of-the-art facilities with a dedicated staff and a variety of production lines. We can handle high-volume requirements efficiently and reliably because of our large scale.